BOTECO Srl

Boteco is the expert company in the design and manufacture of maneuvering handles and mechanical components. More than 400 different product categories for a total of over 15,000 different products. Each product is made using highly reliable materials and according to constantly improved methods, thanks to high investments in design and production technologies.

Our goal?

Offer to the customer:

- excellent value for money,

- innovative products,

- high levels of customization,

- practical use,

- a range in continuous expansion .

BOTECO today

Total area: 13500 m2

Covered Area: 7000 m2

Office area: 1000 m2

Area Services: 450 m2

Production Department Area and Warehouse: 5500 m2

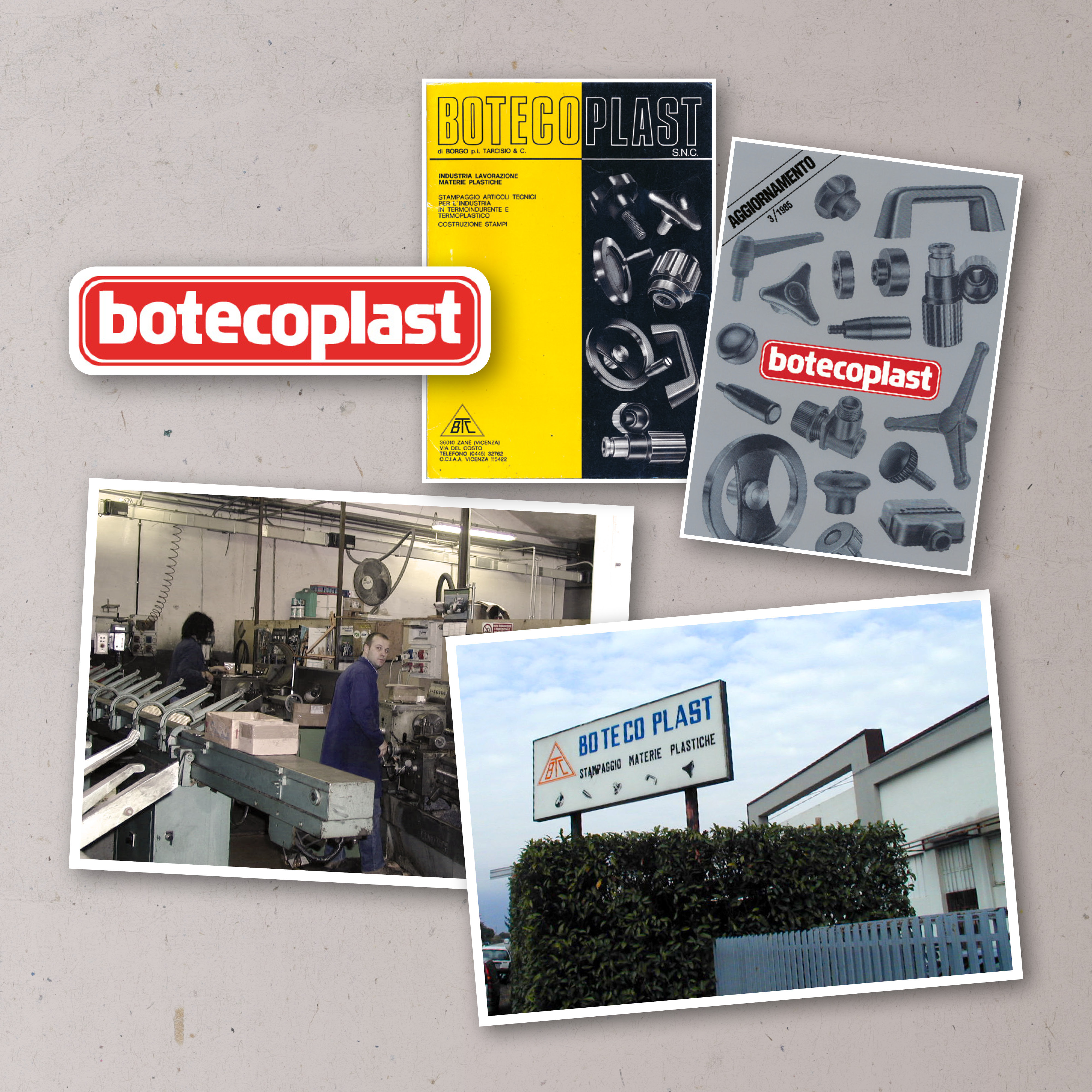

The Boteco story

Founded in the early 1970s under the name of Botecoplast, the company began producing a small range of knobs and moulding a series of special design details, only with thermosetting material (Bakelite, tessilite, etc.), the only available at the time.

In a short time Botecoplast developed an innovative technology for the production of special parts used for the construction of portable welding machines. A sector in which it had so much success that it reached almost 90% of the welding machine manufacturers, thus putting the production of handles in the background.

The situation remained so for several years, until in the early 80s it was decided to resume the development of industrial handles, which were already gathered in a small catalog. This decision was also aided by the introduction on the market of new plastic materials such as reinforced technopolymers (1983) which enabled the company to study new designs and create new product lines.

The first article produced with these materials was the G730 series, leaflet with 4 unloaded lobes. The innovative design and competitive prices decreed the success of this line, spurring the company to start a production conversion process, purchasing new machinery and producing new molds.

In the early 90s the first CNC machines for mold production and molding also arrived. From 1992 he began to design with CAD systems and from 1997 with 3D systems. In the workshop the 2D / 3D CAM helped to realize the new ergonomic lines created in the technical office. From the commercial point of view, after 1990 the distribution network also developed, which led Botecoplast to be known and appreciated all over the world.

In 1999 Botecoplast produced a wide range of grips becoming independent of the welding market. To crown the new road taken, the company decided to change its image: it took away that "PLAST" from the name, which identified it too much as a third party technical printer, and adopted a new logo that could better identify the new range of handles.

Botecoplast became Boteco.

MORE BRANDS, SAME QUALITY

Given the vastness of Boteco products, we have decided to create more lines to identify in a practical and fast way those that stand out for certain qualities.

EUROMODEL

- Products with a sophisticated design and an ergonomic design that increases its grip.

- They often have caps to cover through holes, which can be easily colored without overpricing and facilitate greater customization.

METALLINE

- Products mainly made of metal.

- Robust line suitable for heavy applications where high mechanical strength is required.

LOCKINGS

- Quick fixing systems with mixed technology, metal and plastic products (locks, quick hooks and brackets)

- They are composed according to your needs as clearly specified in the pages of the catalog.

COMPONENTS

To offer a complete range of mechanical components, Boteco has made agreements with strategic partners, starting collaborations, in order to be able to offer elements that go beyond the classic maneuvering handles. These articles are highlighted and collected under the new BOTECO COMPONENTS brand.

BACTERFREE

A range of product from different groups, but with the common feature of being produced using the same ANTIBACTERIAL material that makes them naturally resistant to microbes, bacteria and fungi. All articles belonging to this group have a pad printed logo (BF), so that they can be distinguished from other items having the same appearance, but produced from standard material. On the catalog and website they are highlighted by the presence of the full logo "BacterFree".

ESD-C

Boteco adds the ESD-C (Electrostatic Discharge – Conductive) line to its range of products.

Products already existing in our catalogue such as feet or handles, but made from materials to which fillers are added. This results in a conductive product that allows passive currents such as electrostatic discharges to be grounded, thus preventing dangerous accumulation of the discharges. The ESD items are used in electronic and electrotechnical production lines and in environments with hazardous atmospheres.

The material complies with standards EN 100015/1 and IEC 61340-5-1.

IDENTIFY

Items part of the IDENTIFY line are produced with a material suitable for food contact and are characterised by a Blue RAL 5005 colour. These two characteristics find the best use in the field of machinery and equipment for the food industry. The colour blue makes the items or parts of them easy to locate should they accidentally be put with doughs, bakery products and similar. They can thus be identified, located and separated easily and so avoid being processed together with food.

The inserts part of this range are all Aisi 303 or Aisi 304 certified upon request.

GREEN

With the alignment of the entire production industry to environmental sustainability policies, Boteco too takes a first step towards this objective. With the introduction of the GREEN line, we will start to produce a range of items using a mixed material that features a percentage between 30 % and 50 % of polymer of the same family that is normally employed for that item, but from a certified recycling origin.

This way, we can reduce the CO2 used for our items and help reduce the production of new plastic materials.

UL94 V.0

Products made of self-extinguishing materials with a self-extinguishing grade V0 according to regulation UL94 of the US Underwriter Laboratories.

Moreover, this material has UL yellow card approval necessary for export to the US.